Bring Up: Talon FX/SRX and Victor SPX

At this point all Talon and Victors should appear in Tuner with up to date firmware. The next goal is to drive the motor controller manually. This is done to confirm/test:

Motor and motor wiring

Transmission/Linkage

Mechanism design

Motor Controller drive (both directions)

Motor Controller sensor during motion

Note

Talon FX/SRX and Victor SPX can be used with PWM or CAN bus. This document covers the CAN bus use-case.

Before we enable the motor controller, first check or reset the configs in the next section.

Factory Default Motor Controller

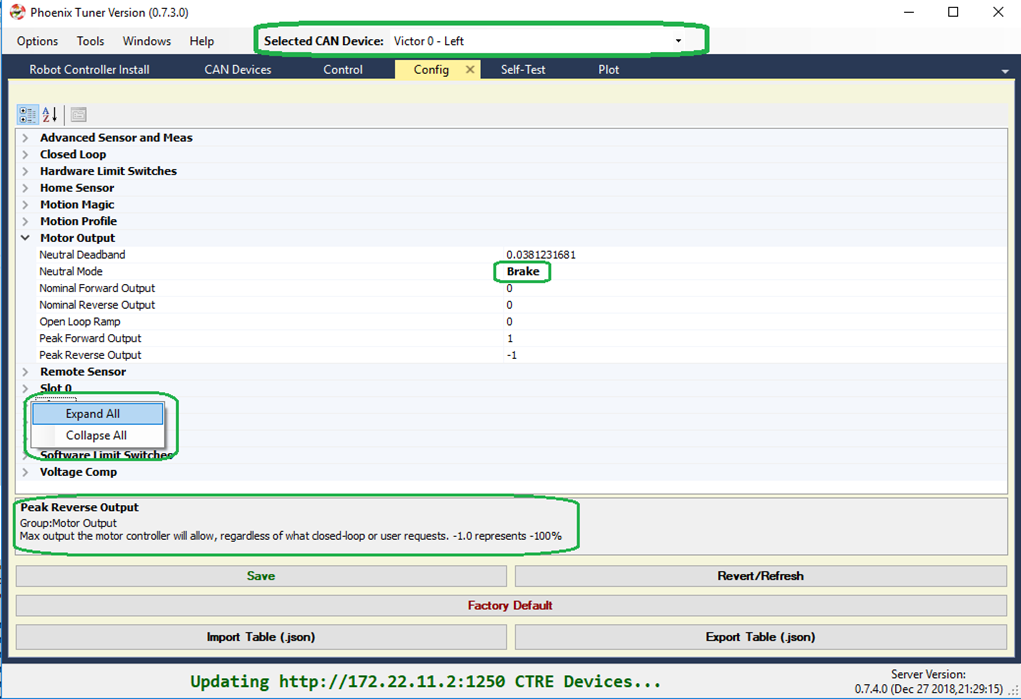

Open the config view to see all persistent settings in the motor controller. This can be done in the config tab (Windows => Config).

Select the Victor or Talon in the center-top dropdown. This will reveal all persistent config settings.

Press Factory Default to default the motor controller settings so that it has predictable behavior.

Tip

There is a modernized version called Tuner X that is available for Windows and Android devices (works with Phoenix 5 and Phoenix Pro).

Tip

Right-click anywhere in the property inspector and select Collapse-all to collapse each config group.

Tip

Other configs can be set in this view for testing purposes. For example, you may want to restrict the maximum output for testing via the Peak output settings under “Motor Output”.

Tip

When a setting is modified, it is set to bold to indicate that it is pending. The bold state will clear after you Save.

Tip

If changing a config live in the robot controller, use the Refresh/Revert button to confirm setting in Tuner.

Note

CTRE devices can be factory defaulted via the API, and through the B/C mechanical button.

Note

Neutral Mode will not change during factory default as it is stored separately from the other persistent configs.

Configuration

Configurable settings are persistent settings that can be modified via the Phoenix API (from robot code) or via Tuner (Config tab). They can also be factory defaulted using either method.

Configs are modified via the config* routines and LabVIEW Vis. There are two general methods for robust operation of a robot. Additionally you can modify the configs via Tuner.

Method 1 – Use the configAll API

Starting with 2019, there is a single routine/VI for setting all of the configs in a motor controller. This ensures that your application does not need to be aware of every single config in order to reliably configure a fresh or unknown motor controller.

This is the recommend API for new robot projects.

Tip

Config structure/object defaults all values to their factory defaults. This means generally you only need to change the settings you care about.

Tip

When using C++/Java, leverage the IntelliSense (Auto-complete) features of the IDE to quickly discover the config settings you need.

Method 2 – Factory Default and config* routines

Phoenix provides individual config* routines for each config setting. Although this is adequate when the number of configs was small, this can be difficult to manage due to the many features/configs in the CTRE motor controllers.

If using individual config routines, we recommend first calling the configFactoryDefault routine/VI to ensure motor controller is restored to a known state, thus allowing you to only config the settings that you intend to change.

This is recommend for legacy applications to avoid porting effort.

Method 3 – Use Tuner

Tuner can be used to get/set/export/import the configs.

However, it is highly recommended to ultimately set them via the software API. This way, in the event a device is replaced, you can rely on your software to properly configured the new device, without having to remember to use Tuner to apply the correct values.

A general recommendation is to:

Configure all devices during robot-bootup using the API,

Use Tuner to dial values quickly during testing/calibration.

Export the settings so they are not lost.

Update your software config values so that Tuner is no longer necessary.

Control Signals

The majority of the behavior in the Talon/Victor is controlled via configs, however there is a small number of control signals that are controlled via the API.

This list includes:

Current Limit Enable (though the thresholds are configs)

Voltage Compensation Enable (though the nominal voltage is a config)

Control Mode and Target/Output demand (percent, position, velocity, etc.)

Invert direction and sensor phase

Closed-loop slot selection [0,3] for primary and aux PID loops.

Neutral mode override (convenient to temporarily override configs)

Limit switch override (convenient to temporarily override configs)

Soft Limit override (convenient to temporarily override configs)

Status Frame Periods

These control signals do not require periodic calls to ensure they “stick”. All of the above signals are automatically restored even after motor controller is power cycled during use except for Status Frame Periods, which can be manually restore by polling for device resets via hasResetOccurred().

Note

WPI motor safety features may require periodic calls to Set() if team software has chosen to enable it.

Note

The override control signals are useful for applications that require temporarily disabling or changing behavior. For example, overriding-disable the soft limits while performing a self-calibration routine to tare sensors, then restoring soft limits for robot operation.

Note

The routines to manipulate control signals are not prefixed with config* to highlight that they are not configs

Test Drive with Tuner

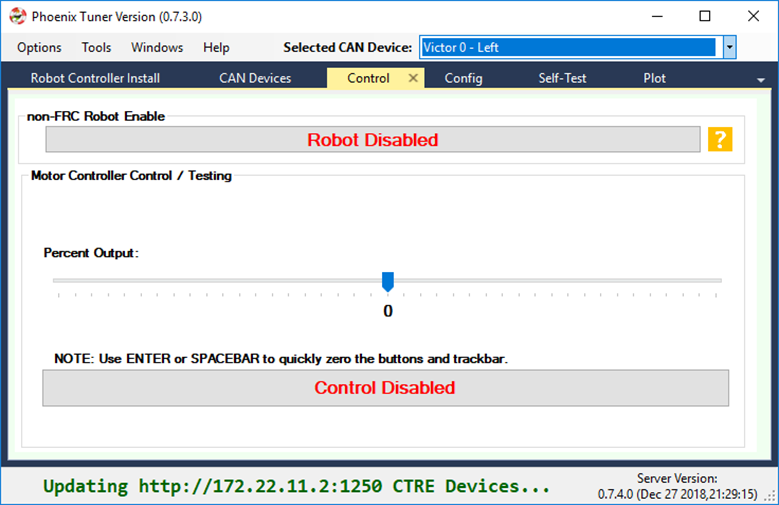

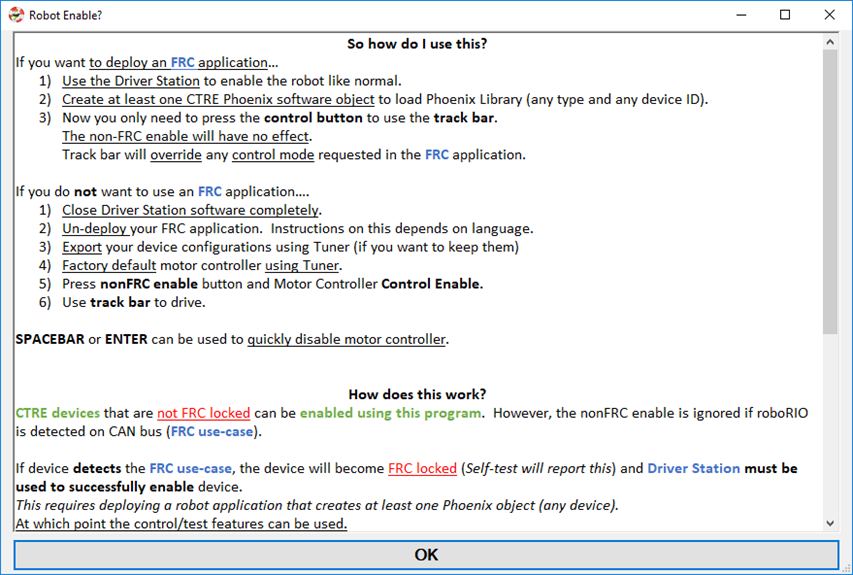

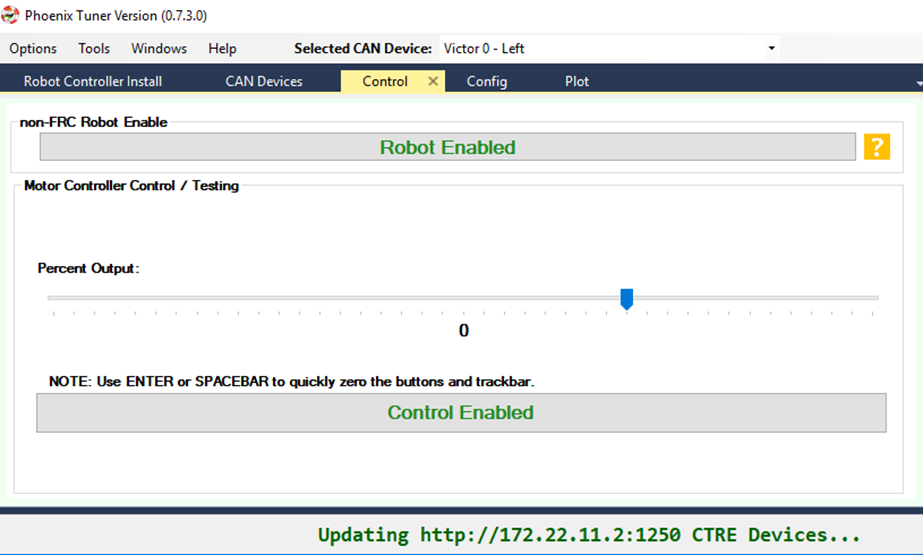

Navigate to the control tab to view the control interface. Notice there are two enable/disable buttons. One is for non-FRC style robot-enable (alternative to the Driver Station enable), and one is for Motor Controller Control-Enable.

Press on the question mark next to the robot disabled/enabled button.

This will reveal the full explanation of how to safely enable your motor controller. Follow the appropriate instructions depending on if you want to use Driver Station for your robot-enable.

Setting up non-FRC Control

In order to enable without the Driver Station you must use a non-roboRIO platform and disconnect the roboRIO from the CAN bus.

With an FRC roboRIO, you must always use the Driver Station to enable.

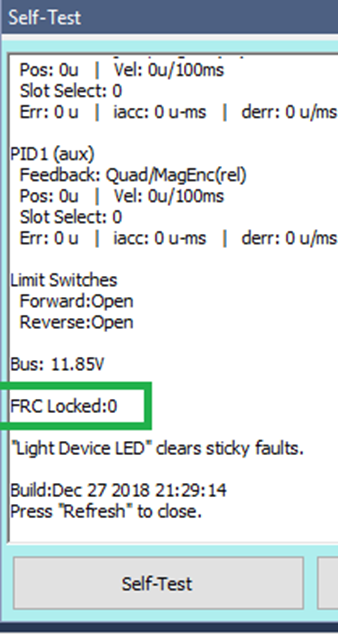

Confirm FRC Unlock

Self-test Snapshot Motor Controller to confirm device FRCLocked = 0.

If device is FRC Locked (=1), use factory default in the config tab to clear the state. Note that if an FRC roboRIO is on the CAN bus, the motor controller will immediately FRC Lock again.

Note

Use the config export tool if you need to keep your config settings.

Control tab

Press both Robot Enabled and Control Enabled. At this point you can use the track bar to drive the Victor/Talon.

Note

If you do connect with a roboRIO, the Talon/Victor will FRC Lock again. At which point you must use the driver station to enable, and you no longer need to use the non-FRC Robot enable in Tuner.

Note

Spacebar or enter can be used to clear the control tab and neutral the selected motor controller.

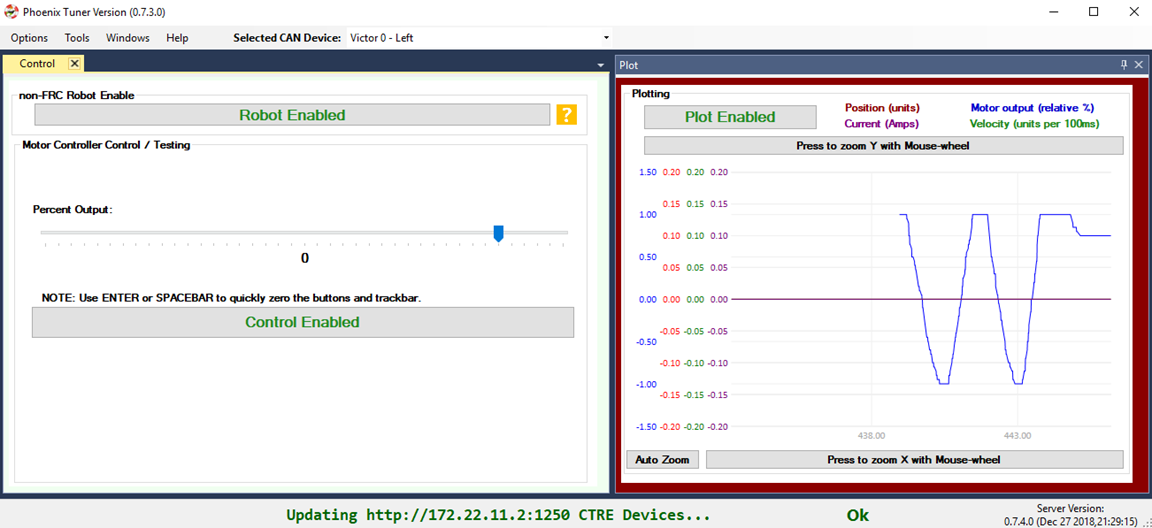

Plot tab

Now open the Plot window. Drive the motor controller while observing the plot. Confirm the blue motor output curve matches LED behavior and trackbar. Confirm motor movement follows expectations.

Note

Press the Plot enable button to effectively pause the plot for review

Note

Use the Zoom buttons to select whether the mouse adjust the Y or X axis.

Note

If using a Victor SPX, current-draw will always read zero (SPX does not have current-measurement features).

Tip

Plot can be used anytime, regardless of what is commanding the motor controller (FRC or non-FRC).

Test Drive with Robot Controller

Next we will create control software in the roboRIO. Currently this is necessary for more advanced control. This is also required for controlling your robot during competition.

Tip

The latest version of Tuner allows for testing most closed-loop control modes without writing software.

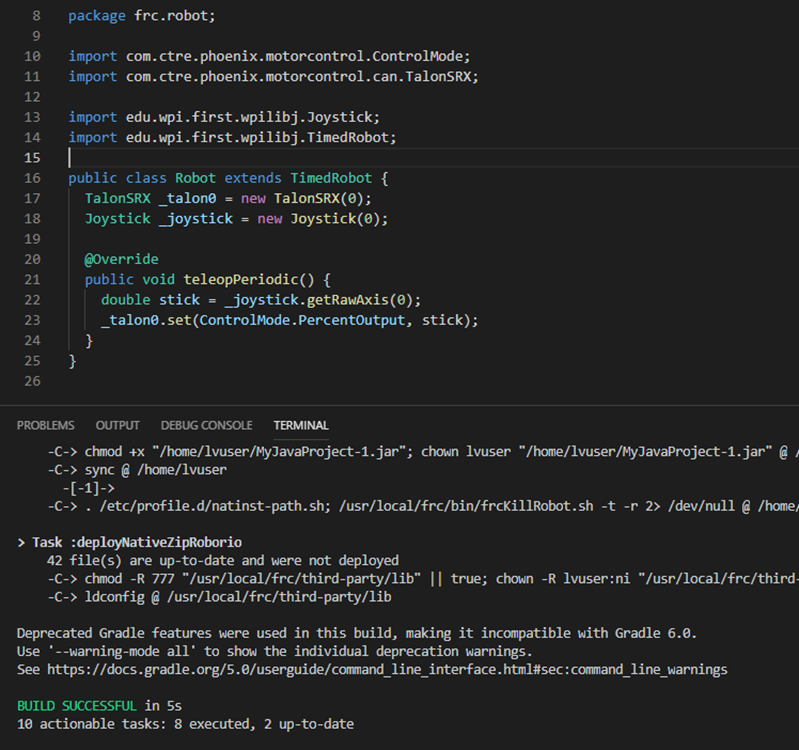

Java: Sample driving code

Below is a simple example that reads the Joystick and drives the Talon

package frc.robot;

import com.ctre.phoenix.motorcontrol.ControlMode;

import com.ctre.phoenix.motorcontrol.can.TalonSRX;

import edu.wpi.first.wpilibj.Joystick;

import edu.wpi.first.wpilibj.TimedRobot;

public class Robot extends TimedRobot {

TalonSRX _talon0 = new TalonSRX(0); // Change '0' to match device ID in Tuner. Use VictorSPX for Victor SPXs

Joystick _joystick = new Joystick(0);

@Override

public void teleopPeriodic() {

double stick = _joystick.getRawAxis(1);

_talon0.set(ControlMode.PercentOutput, stick);

}

}

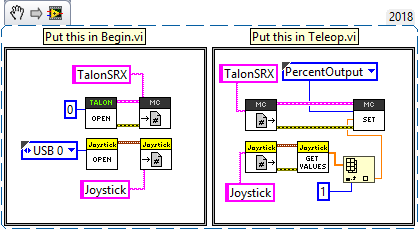

Tip

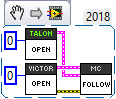

Image below can be dragged/dropped into LabVIEW editor.

Deploy the project, and confirm success.

Note

WPI’s terminal output may read “Build” successful despite the project was deployed.

Note

Before you enable the DS, spin the Joystick axis so it reaches the X and Y extremities are reached. USB Gamepads calibrate on-the-fly so if the Gamepad was just inserted into the DS, it likely has not auto detected the max mechanical range of the sticks.

Note

Make sure joystick is detected by the DS before enabling.

Note

getRawAxis may not return a positive value on forward-stick. Confirm this by watching Talon/Victor LED. Green suggests a positive output.

Enable the Driver Station and confirm:

motor drive in both directions using gamepad stick.

motor controller LEDs show green for forward and red for reverse

Disable Driver Station after finished testing.

Note

If the LED is solid orange than use Tuner to determine the cause. Self-test Snapshot will report the current state of the motor controller (do this while troubleshooting). Confirm firmware is up to date.

Open-Loop Features

After some rudimentary testing, you will likely need to configure several open-loop features of the Talon SRX and Victor SPX.

Note

We recommend configuring Inverts and Followers first.

Inverts

To determine the desired invert of our motor controller, we will add two more lines of call. SetInverted is added to decide if motor should spin clockwise or counter clockwise when told to move positive/forward (green LEDs).

Note

The selected sensor’s values are also inverted accordingly so the sensor phase does not need to be adjusted based on motor inversion.

We also multiply the joystick so that forward is positive (intuitive). This can be verified by watching the console print in the Driver Station.

package frc.robot;

import com.ctre.phoenix.motorcontrol.*;

import com.ctre.phoenix.motorcontrol.can.*;

import edu.wpi.first.wpilibj.Joystick;

import edu.wpi.first.wpilibj.TimedRobot;

public class Robot extends TimedRobot {

TalonSRX _talon0 = new TalonSRX(0);

Joystick _joystick = new Joystick(0);

@Override

public void teleopInit() {

_talon0.setInverted(false); // pick CW versus CCW when motor controller is positive/green

}

@Override

public void teleopPeriodic() {

double stick = _joystick.getRawAxis(1) * -1; // make forward stick positive

System.out.println("stick:" + stick);

_talon0.set(ControlMode.PercentOutput, stick);

}

}

Tip

Image below can be dragged/dropped into LabVIEW editor.

Talon FX Specific Inverts

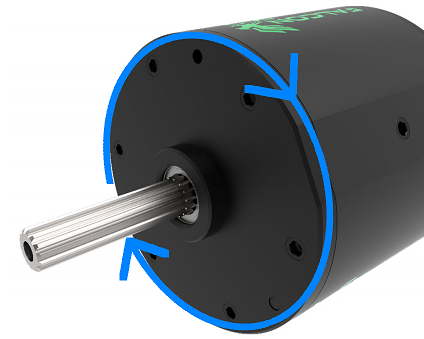

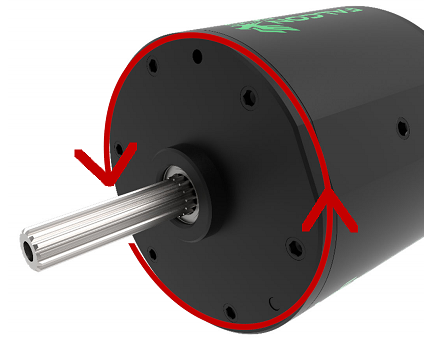

Talon FX has a new set of inverts that are specific to it, TalonFXInvertType.Clockwise and TalonFXInvertType.CounterClockwise. These new inverts allow the user to know exactly what direction the Falcon 500 will spin. These inverts are from the perspective of looking at the face of the motor.

Below is an image demonstrating the Falcon’s Clockwise rotation:

And below is the Falcon’s CounterClockwise rotation:

Follower

If a mechanism requires multiple motors, than there are likely multiple motor controllers. The Follower feature of the Talon FX/SRX and Victor SPX is a convenient method to keep two or more motor controller outputs consistent. If you have an external sensor for closed-looping, connect that to the “master” Talon SRX (unless it is a remote sensor such as CANcoder/CANifier/Pigeon).

Below we’ve added a new Victor to follow Talon 0.

Generally, a follower is intended to match the direction of the master, or drive in the opposite direction depending on mechanical orientation. In previous seasons teams would have to update the bool true/false of the follower to match or oppose the master manually.

Starting in 2019, C++/Java users can set the setInverted(InvertType) to instruct the motor controller to either match or oppose the direction of the master instead.

package frc.robot;

import com.ctre.phoenix.motorcontrol.*;

import com.ctre.phoenix.motorcontrol.can.*;

import edu.wpi.first.wpilibj.Joystick;

import edu.wpi.first.wpilibj.TimedRobot;

public class Robot extends TimedRobot {

TalonSRX _talon0 = new TalonSRX(0);

VictorSPX _victor0 = new VictorSPX(0);

Joystick _joystick = new Joystick(0);

@Override

public void teleopInit() {

_victor0.follow(_talon0);

_talon0.setInverted(false); // pick CW versus CCW when motor controller is positive/green

_victor0.setInverted(InvertType.FollowMaster); // match whatever talon0 is

//_victor0.setInverted(InvertType.OpposeMaster); // opposite whatever talon0 is

}

@Override

public void teleopPeriodic() {

double stick = _joystick.getRawAxis(1) * -1; // make forward stick positive

System.out.println("stick:" + stick);

_talon0.set(ControlMode.PercentOutput, stick);

}

}

Tip

Image below can be dragged/dropped into LabVIEW editor.

Note

LabVIEW does not support using InvertType to follow master or oppose master

Enable the Driver Station and slowly drive both MCs from neutral. Confirm both LEDs are blinking the same color.

Disable Driver Station when complete.

To confirm motor controllers are truly driving in the same direction, disconnect the master motor controller from its motor.

Enable the Driver Station and confirm follower motor direction matches previously measured master motor direction.

Disable Driver Station when complete.

Open Tuner and select the master motor controller.

Open plot tab and enable plotter while driving motor controller

Confirm current plot is appropriate. If motors are free-spinning, then current should be near 0 if motor output is constant. When testing drive train, the robot should be rested on a crate/tote to ensure all wheels spin freely.

Select follower motor in Tuner, and confirm current via plot.

Note

Follower mode can be canceled by calling set() with any other control mode, or calling neutralOutput().

Note

Calling follow() in the periodic loop is not required, but also does not affect anything in a negative way.

Controlling Followers with Phoenix Tuner

Oftentimes you want to test/tune a mechanism with a master motor controller and one or more followers. This can be accomplished with Phoenix Tuner in the same manner as if there was only one controller, as long as the followers are configured to follow the master. This means you cannot run a temporary diagnostic server to control multiple motor controllers at the same time.

It is imperative to make sure the followers are configured correctly by following the steps above. The followers will use their settings from the user application, even when following a master controlled by Tuner.

Tip

This is the recommended way to tune two or more mechanically linked motors. By having one motor controller as a master, it will handle the PID closed looping while all followers match the applied output of the master.

Neutral Mode

You may note that when the motor output transitions to neutral, the motors free spin (coast) in the last direction they were driven. If the Talon/Victor is set to “coast” neutral mode, then this is expected. The neutral mode can also be set to “brake” to electrically common the motor leads during neutral, causing a deceleration that combats the spinning motor motion.

Tip

You can use Talon FX’s ConfigStatorCurrentLimit method to dial in how strong the brake is.

Note

SetNeutralMode() can be used change the neutral mode on the fly.

TalonSRX talon = new TalonSRX(0);

talon.setNeutralMode(NeutralMode.Brake);

Tip

Image below can be dragged/dropped into LabVIEW editor.

Follower motor controllers have separate neutral modes than their masters, so you must choose both. Additionally, you may want to mix your neutral modes to achieve a partial electric brake when using multiple motors.

Neutral Deadband

A device’s neutral deadband is the region where the controller demotes its output to neutral. This can be configured in your robot code, with a default value of 0.04 or 4%, and a range of [0.001, 0.25] or [0.1%, 25%].

_talon.configNeutralDeadband(0.001); /* Configures _talon to use a neutral deadband of 0.1% */

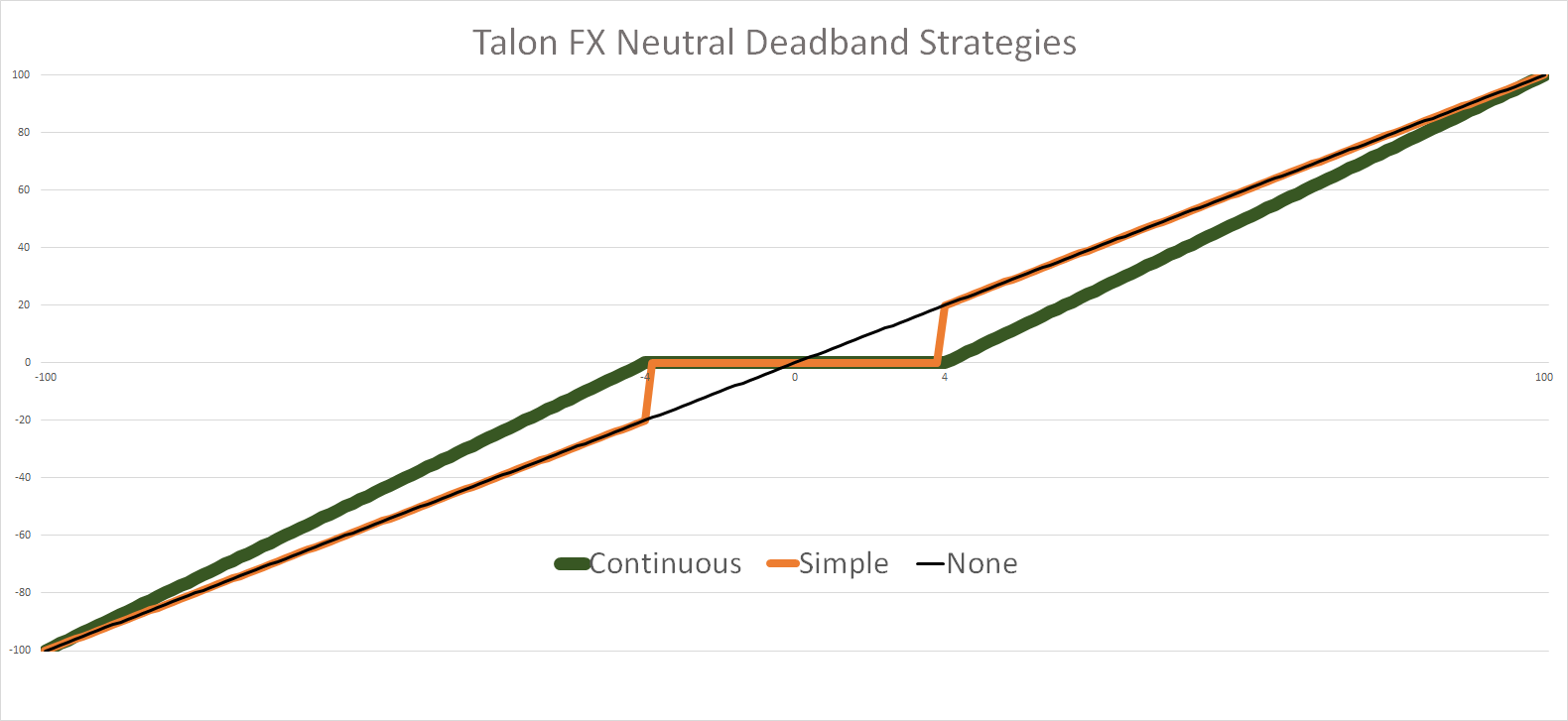

Talon FX has 3 different deadband strategies based on its state. They are Simple, Continuous, and None.

A Simple deadband will demote any requested output within the region to neutral, and otherwise uphold the requested demand. An example of this is with a configured deadband of 4% and a requested output of 4% will be 0%, 5% output will be 5%, and 100% will be 100%. This is used in the majority of circumstances so it’s obvious that the requested output is the applied output outside the neutral deadband.

A Continuous deadband is similar to a simple deadband in that it demotes any requested output within the region to neutral, but outside the region it will scale the applied output so it’s continuous out of the deadband thresholds. This allows for a smooth transition out of neutral. With a 4% deadband, a requested output of 4% will result in an applied output of 0%, requesting 5% will bring it to 1%, and 100% will be 100%.

A None deadband will not uphold the deadband whatsoever. A deadband of 4% with 4% requested output will apply 4%, 5% is 5%, and 100% is 100%. This is used only in follower mode so you don’t have to configure the deadband of your followers, only of the master.

The below graph highlights this, exaggerating the effect to make it obvious.

The below table details what neutral deadband strategy the Talon FX uses under the various states.

Mode |

Condition |

Deadband Type |

|---|---|---|

PWM Control |

X |

Continuous |

Percent Output |

Voltage Compensation Disabled |

Continuous |

Percent Output |

Voltage Compensation Enabled |

Simple |

Closed Loop |

X |

Simple |

Auxiliary Follower |

X |

Simple |

Follower |

X |

None |

Ramping

The motor controller can be set to honor a ramp rate to prevent instantaneous changes in throttle. This ramp rate is in effect regardless of which mode is selected (throttle, follower, or closed-loop).

Ramp can be set in time from neutral to full using configOpenLoopRampRate().

Note

configClosedLoopRampRate() can be used to select the ramp during closed-loop (sensor) operations.

Note

The slowest ramp possible is ten seconds (from neutral to full), though this is quite excessive.

TalonSRX talon = new TalonSRX(0);

talon.configOpenloopRamp(0.5); // 0.5 seconds from neutral to full output (during open-loop control)

talon.configClosedloopRamp(0); // 0 disables ramping (during closed-loop control)

Tip

Images below can be dragged/dropped into LabVIEW editor.

Peak/Nominal Outputs

Often a mechanism may not require full motor output. The application can cap the output via the peak forward and reverse config setting (through Tuner or API).

Additionally, the nominal outputs can be selected to ensure that any non-zero requested motor output gets promoted to a minimum output. For example, if the nominal forward is set to +0.10 (+10%), then any motor request within (0%, +10%) will be promoted to +10% assuming request is beyond the neutral dead band. This is useful for mechanisms that require a minimum output for movement, and can be used as a simpler alternative to the kI (integral) component of closed-looping in some circumstances.

Voltage Compensation

Talon FX/SRX and Victor SPX can be configured to adjust their outputs in response to the battery voltage measurement (in all control modes). Use the voltage compensation saturation config to determine what voltage represents 100% output.

Then enable the voltage compensation using enableVoltageCompensation().

Advanced users can adjust the Voltage Measurement Filter to make the compensation more or less responsive by increasing or decreasing the filter. This is available via API and via Tuner

TalonSRX talon = new TalonSRX(0);

talon.configVoltageCompSaturation(11); // "full output" will now scale to 11 Volts for all control modes when enabled.

talon.enableVoltageCompensation(true); // turn on/off feature

Tip

Image below can be dragged/dropped into LabVIEW editor.

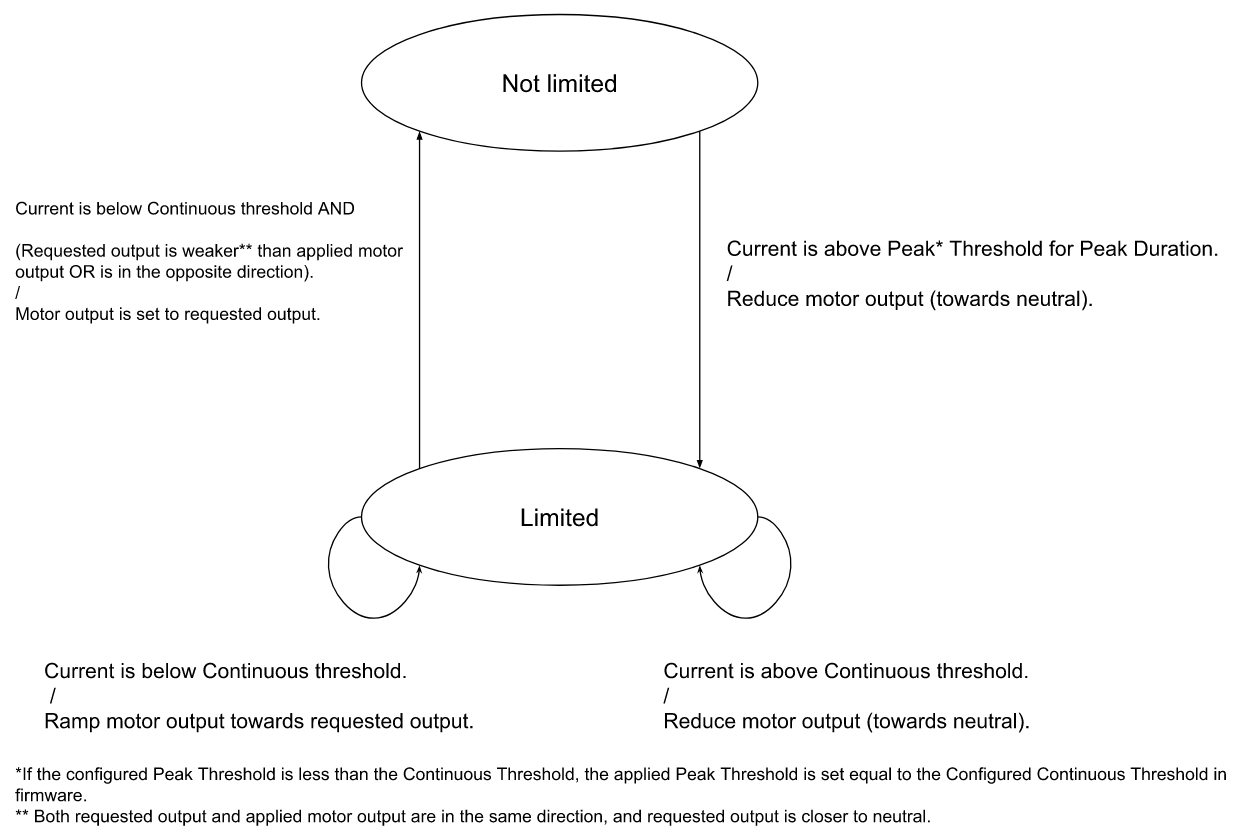

Current Limit

Legacy API

Talon FX/SRX supports current limiting in all control modes.

The limiting is characterized by three configs:

Peak Current (Amperes), threshold that must be exceeded before limiting occurs.

Peak Time (milliseconds), thresholds that must be exceed before limiting occurs

Continuous Current (Amperes), maximum allowable current after limiting occurs.

TalonSRX talon = new TalonSRX(0);

talon.configPeakCurrentLimit(30); // don't activate current limit until current exceeds 30 A ...

talon.configPeakCurrentDuration(100); // ... for at least 100 ms

talon.configContinuousCurrentLimit(20); // once current-limiting is activated, hold at 20A

talon.enableCurrentLimit(true);

Tip

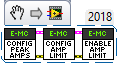

Image below can be dragged/dropped into LabVIEW editor.

If enabled, Talon SRX will monitor the supply-current looking for a conditions where current has exceeded the Peak Current for at least Peak Time. If detected, output is reduced until current measurement is at or under Continuous Current.

Note

If Peak current limit is set less than continuous limit, peak current limit will be set equal to continuous current limit.

Once limiting is active, current limiting will deactivate if motor controller can apply the requested motor output and still measure current-draw under the Continuous Current Limit.

After setting the three configurations, current limiting must be enabled via enableCurrentLimit() or LabVIEW VI.

Note

Use Self-test Snapshot to confirm if Current Limiting is occurring

Note

If peak limit is less than continuous limit, peak is set equal to continuous

Note

If you only want continuous limiting, you should set peak limit to 0

New API in 2020

Talon FX supports both stator(output) current limiting and supply(input) current limiting.

Supply current is current that’s being drawn at the input bus voltage. Stator current is current that’s being drawn by the motor.

Supply limiting (supported by Talon SRX and FX) is useful for preventing breakers from tripping in the PDP.

Stator limiting (supported by Talon FX) is useful for limiting acceleration/heat.

The new API leverages the configSupplyCurrentLimit and configStatorCurrentLimit routines. The configs are similar to the existing legacy API, but the configs have been renamed to better communicate the design intent. For example, instead of configPeakCurrentLimit, the setting is referred to as triggerThresholdCurrent.

/**

* Configure the current limits that will be used

* Stator Current is the current that passes through the motor stators.

* Use stator current limits to limit rotor acceleration/heat production

* Supply Current is the current that passes into the controller from the supply

* Use supply current limits to prevent breakers from tripping

*

* enabled | Limit(amp) | Trigger Threshold(amp) | Trigger Threshold Time(s) */

_tal.configStatorCurrentLimit(new StatorCurrentLimitConfiguration(true, 20, 25, 1.0));

_tal.configSupplyCurrentLimit(new SupplyCurrentLimitConfiguration(true, 10, 15, 0.5));

An example of this is available on our Github Examples repository

Reading status signals

The Talon FX/SRX and Victor SPX transmit most of their status signals periodically, i.e. in an unsolicited fashion. This improves bus efficiency by removing the need for “request” frames, and guarantees that the signals necessary for the wide range of use cases they support are available.

These signals are available in API regardless of what control mode the Talon SRX is in. Additionally the signals can be polled using Phoenix Tuner using the Self-test Snapshot button.

Included in the list of signals are:

Quadrature Encoder Position, Velocity, Index Rise Count, Pin States (A, B, Index)

Analog-In Position, Analog-In Velocity, 10bit ADC Value,

Battery Voltage, Current, Temperature

Fault states, sticky fault states,

Limit switch pin states

Applied Throttle (duty cycle) regardless of control mode.

Applied Control mode: Voltage % (duty-cycle), Position/Velocity closed-loop, or follower.

Brake State (coast vs brake)

Closed-Loop Error, the difference between closed-loop set point and actual position/velocity.

Sensor Position and Velocity, the signed output of the selected Feedback device (robot must select a Feedback device, or rely on default setting of Quadrature Encoder).

Integrated Sensor (Talon FX).

Magnet position and strength (CANCoder).

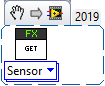

Tip

In LabVIEW, these signals can all be obtained from the “Get” VI from the motor controller’s sub-palette. Choose the type of signals desired from the VI’s drop-down menu.

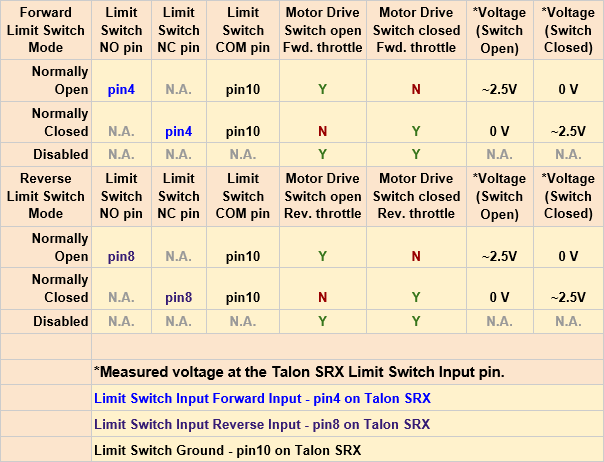

Limit Switches

Talon SRX and Victor SPX have limit features that will auto-neutral the motor output if a limit switch activates. Talon SRX in particular can automatically do this when limit switches are connected via the Gadgeteer feedback port.

An “out of the box” Talon will default with the limit switch setting of “Normally Open” for both forward and reverse. This means that motor drive is allowed when a limit switch input is not closed (i.e. not connected to ground). When a limit switch input is closed (is connected to ground) the Talon SRX will disable motor drive and individually blink both LEDs red in the direction of the fault (red blink pattern will move towards the M+/white wire for positive limit fault, and towards M-/green wire for negative limit fault).

Since an “out of the box” Talon will likely not be connected to limit switches (at least not initially) and because limit switch inputs are internally pulled high (i.e. the switch is open), the limit switch feature is default to “normally open”. This ensures an “out of the box” Talon will drive even if no limit switches are connected.

For more information on Limit Switch wiring/setup, see the Talon SRX User’s Guide.

Limit switch features can be disabled or changed to “Normally Closed” in Tuner and in API.

Note

When the source is set to Gadgeteer, the “Device ID” field is ignored. This config is used for remote limit switches (see next section).

Confirm the limit switches are functional by applying a weak positive motor output while tripping the forward limit switch.

Note

The motor does not have to be physically connected to the motor-controller if tester can artificially assert physical limit switch.

/* Configured forward and reverse limit switch of Talon to be from a feedback connector and be normally open */

Hardware.leftTalonMaster.configForwardLimitSwitchSource(LimitSwitchSource.FeedbackConnector, LimitSwitchNormal.NormallyOpen, 0);

Hardware.leftTalonMaster.configReverseLimitSwitchSource(LimitSwitchSource.FeedbackConnector, LimitSwitchNormal.NormallyOpen, 0);

Limit Switch Override Enable

The enable state of the limit switches can be overridden in software. This can be called at any time to enable or disable both limit switches.

Generally you should call this instead of a config if you want to dynamically change whether you are using the limit switch or not inside a loop. This value is not persistent across power cycles.

/* Limit switches are forced disabled on Talon and forced enabled on Victor */

Hardware.leftTalonMaster.overrideLimitSwitchesEnable(false);

Hardware.rightVictorMaster.overrideLimitSwitchesEnable(true);;

Limit Switch As Digital Inputs

Limit switches can also be treated as digital inputs. This is done in Java/C++ by using the isFwdLimitSwitchClosed & isRevLimitSwitchClosed method.

_talon.getSensorCollection().isFwdLimitSwitchClosed();

_talon.getSensorCollection().isRevLimitSwitchClosed();

Note

The sensor being closed returns true in all cases, and the sensor being open returns false in all cases, regardless of normally open/normally closed setting. This ensures there is no ambiguity in the function name.

Remote Limit Switches

A Talon SRX or Victor SPX can use a remote sensor as the limit switch (such as another Talon SRX or CANifier).

Change the Limit Forward/Reverse Source to Remote Talon or Remote CANifier. Then config the Limit Forward/Reverse Device ID for the remote Talon or CANifier.

/* Configured forward and reverse limit switch of a Victor to be from a Remote Talon SRX with the ID of 3 and normally closed */

Hardware.rightVictorMaster.configForwardLimitSwitchSource(RemoteLimitSwitchSource.RemoteTalonSRX, LimitSwitchNormal.NormallyClosed, 3, 0);

Hardware.rightVictorMaster.configReverseLimitSwitchSource(RemoteLimitSwitchSource.RemoteTalonSRX, LimitSwitchNormal.NormallyClosed, 3, 0);

Use Self-test Snapshot on the motor-driving motor controller to confirm limit switches are interpreted correctly. If they are not correct, then Self-test Snapshot the remote device to determine the issue.

Soft Limits

Soft limits can be used to disable motor drive when the “Sensor Position” is outside of a specified range. Forward throttle will be disabled if the “Sensor Position” is greater than the Forward Soft Limit. Reverse throttle will be disabled if the “Sensor Position” is less than the Reverse Soft Limit. The respective Soft Limit Enable must be enabled for this feature to take effect.

/* Talon configured to have soft limits 10000 native units in either direction and enabled */

rightMaster.configForwardSoftLimitThreshold(10000, 0);

rightMaster.configReverseSoftLimitThreshold(-10000, 0);

rightMaster.configForwardSoftLimitEnable(true, 0);

rightMaster.configReverseSoftLimitEnable(true, 0);

The settings can be set and confirmed in Phoenix Tuner